Custom Injection Molding

Committed to excellence, innovation and customer satisfaction

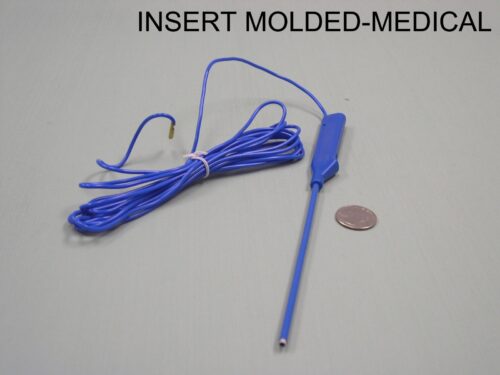

Insert Molding

"Insert Molding: Strengthening Bonds, Enhancing Efficiency Insert molding involves placing a pre-made part into a mold for plastic to form around, creating a robust bond. Benefits include increased strength, secure fastening, and simplified assembly, often at a lower cost.

Two-Shot Molding

"Two-Shot Molding: Streamlining Production, Enhancing Quality Two-shot molding combines two polymers injected through separate nozzles to create a single part, eliminating assembly steps. This process offers diverse benefits, including versatile surface textures, sealing capabilities, movable components, and color integration.

Engineering Resins

At Pilgrim Innovative Plastics, LLC, we've used a wide variety of engineering resins in product development as well as production. Whether you're just beginning to consider engineering materials or you've been using them for years and just aren't happy with the results, bring your product to PIPLLC and we'll help you determine the best course of action. We have the experience to know when commodity plastics aren't going to be enough, the knowledge to find the right substitute, and the expertise to consistently manufacture quality parts.

Assembly

At Pilgrim Innovative Plastics, we'll use our extensive experience to help you develop an assembly procedure in-house during development and early production that you can continue to use as business ramps up. We have the tools, space, labor, and expertise needed to develop or optimize your assembly procedure without you needing to worry about the overhead expenses until your product can support itself.

Pilgrim Innovative Plastics

Innovation At Work

Pilgrim prides itself on innovation. Our fleet of Milacron Roboshot Electric Injection Molding Machines ensures precision and efficiency.

TESTIMONIALS

What Our Clients Say About Us

“I have been a client of Pilgrim Innovative Plastics for over 6 years. They manufacture my product, the Handyaid Jar & Bottle Opener. I couldn’t be more pleased with my decision to partner with them. I am a nurse, and took over my father’s business. I knew nothing of this field, and needed to trust a new manufacturer to help me reboot.

Pilgrim was able to find the perfect material and color to produce the exact product that I needed. My father sold these jar openers (patented as the first ever jar opener in 1942) for decades, made of rubber. I needed to change from rubber to plastic, but maintain the grip and pliability of rubber. Pilgrim worked hard to find the perfect solution for me, and I am so happy with the product. My customers rave to me all the time on how well they work! I sell thousands of them all over the world.

The whole team there is wonderful, professional and competent. The turnover time from order to completion is always just a few weeks. I appreciate them, and would highly recommend Pilgrim Innovative Plastics. I’m glad I found them!

Karen Clinton R.N.

Handyaid Company”